1. Quality

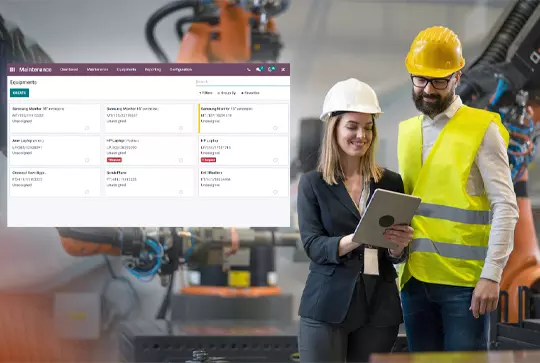

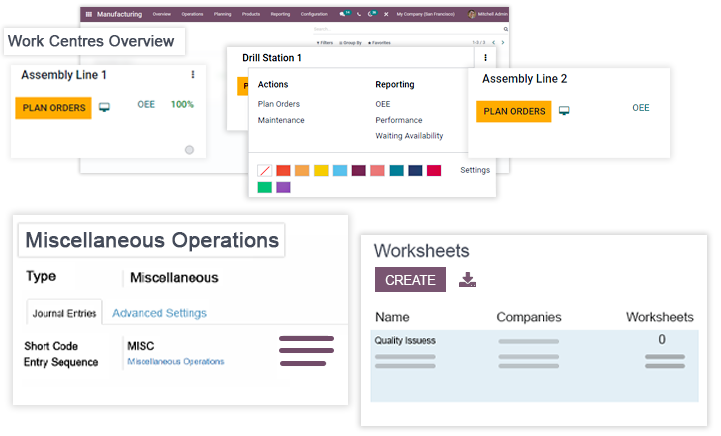

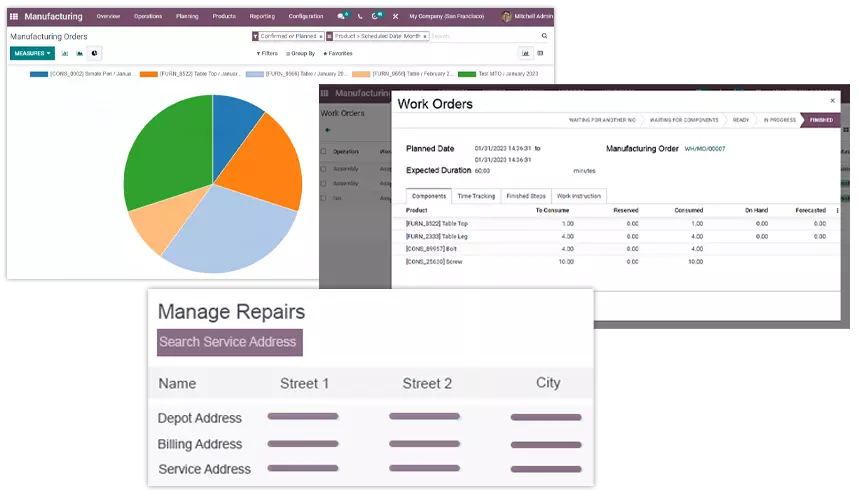

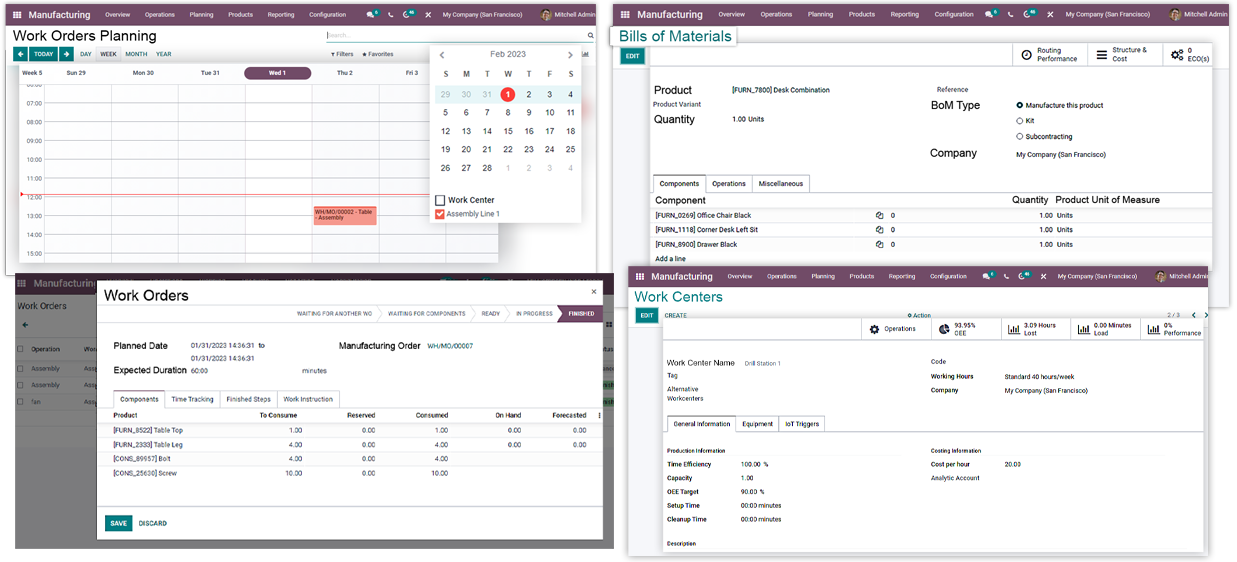

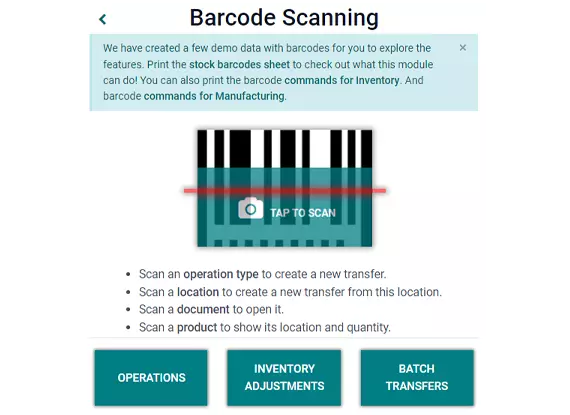

One should confirm the quality of the goods your business produces. The business performs a number of quality-checking methods on the finished product before delivering it to the customer to ensure it meets quality standards. O2b Technologies brings the best Odoo quality management system, that is able to manage these tasks through a single platform.

The business has evolved along with technological and operational capabilities, and so have individuals and experts. Today, a variety of solutions, particularly for various functional elements, are employed in corporate operations and management. There are more options to select from in every area of business operations and management, particularly in relation to business management systems. Odoo is one of the well-known tools for quality management that stands out among other options for offering dependability and efficiency in management operations.

USA

USA INDIA

INDIA