ERP Software For Plastic Industry

A Robust Solution for all of your Plastic Manufacturing Operations

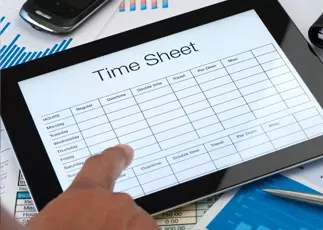

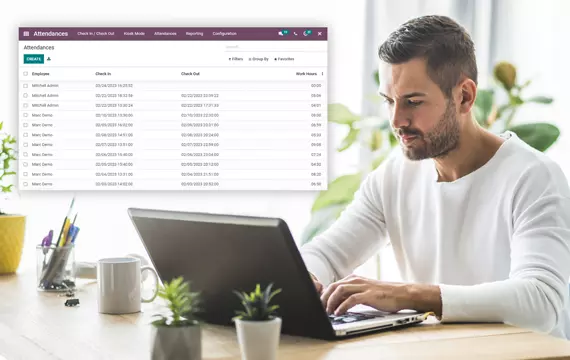

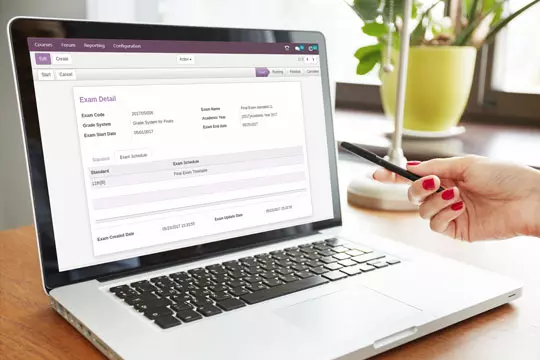

Plastic manufacturing is becoming a very important and large industry of business with several potentials and uses. ERP software is required for the plastic manufacturing business to manage all activities properly and without the possibility of errors. O2b Technologies provides the best ERP solution that makes overall operations easier and simpler.

Eco-friendly Plastic Manufacturing

Eco-friendly Plastic Manufacturing Meeting the Standard

Meeting the Standard Ecosystem Concerns

Ecosystem Concerns Rising Competition

Rising Competition

USA

USA INDIA

INDIA