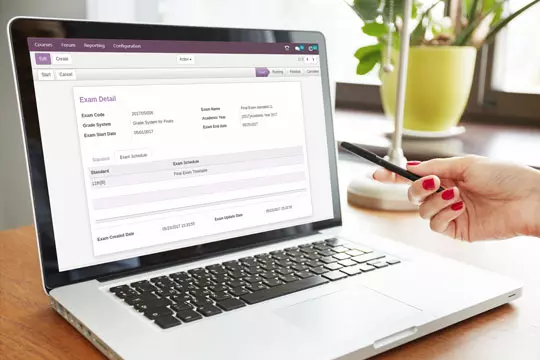

Your subject & DevOps tools can be integrated with your quality assurance management tool to track software bugs and incidents, identify problematic test suites, track key quality metrics, and manage all testing activities in one location.

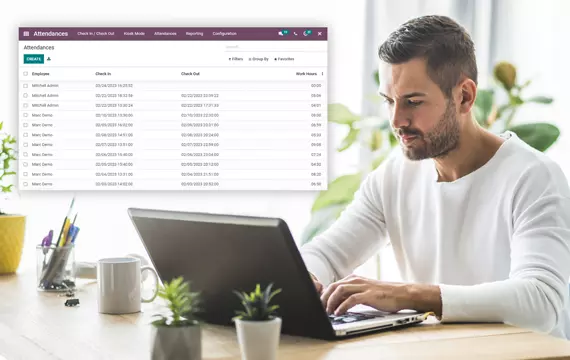

A tightly controlled company must maintain thorough and compliant quality management in order to continue developing new products, launching them quickly to market, and sustaining growth. Paper-based processes are no longer sufficient in today's fiercely highly competitive market because it requires the appropriate systems and tools. Digital quality management software (QMS) from O2b Technologies automates quality throughout the entire product life cycle, assisting businesses in navigating constantly evolving regulations and standards, streamlining procedures, proving compliance, and turning quality into a true competitive differentiation strategy.

USA

USA INDIA

INDIA